In today’s rapidly evolving manufacturing landscape, precision engineering demands unparalleled accuracy and efficiency. CNC machining services have become an essential solution for industries requiring intricate, high-quality components with tight tolerances. Whether in aerospace, medical devices, automotive, or electronics, the advantages of CNC machining services enable engineers and manufacturers to meet rigorous specifications while maintaining cost-effectiveness and speed. This article explores the key benefits of CNC machining services and why they are indispensable for precision engineering projects.

What Are CNC Machining Services?

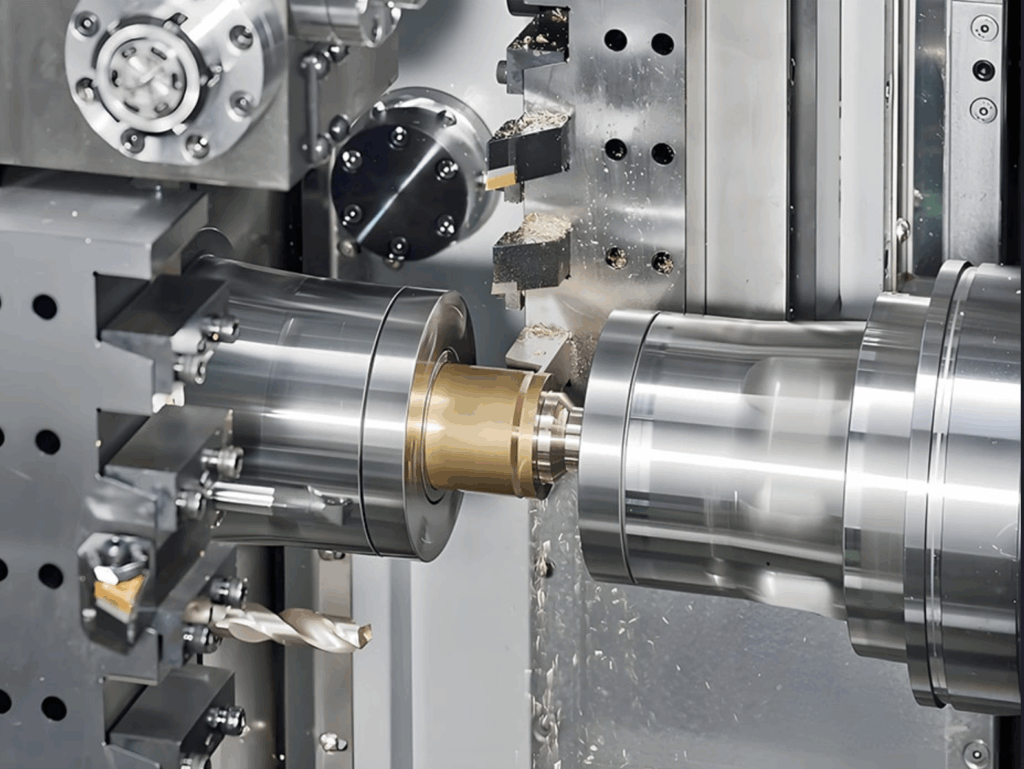

CNC machining services refer to manufacturing processes that use Computer Numerical Control (CNC) machines to automate the production of parts and components. These machines operate based on programmed instructions, allowing precise control over cutting tools and movements. Unlike traditional manual machining, CNC machining services offer consistency, repeatability, and high precision by eliminating human error.

The technology supports various machining operations such as milling, turning, drilling, and grinding, producing complex geometries from a wide range of materials including metals, plastics, and composites. This versatility makes CNC machining services a cornerstone of modern precision engineering.

Enhanced Precision and Accuracy

One of the foremost benefits of CNC machining services is the ability to achieve extremely high levels of precision and accuracy. The computer-controlled nature of these machines ensures that every cut, drill, or turn is executed with minimal deviation. This is crucial for precision engineering projects where tolerances are often measured in microns.

The software-driven process eliminates variability caused by human factors, resulting in consistent parts that meet exact design specifications. This precision is particularly vital in industries like aerospace and medical device manufacturing, where even the slightest deviation can lead to critical failures or safety risks.

Improved Efficiency and Productivity

CNC machining services significantly boost manufacturing efficiency. Once a program is set up, machines can operate continuously with minimal supervision, reducing downtime and speeding up production cycles. This ability to run unattended not only increases throughput but also lowers labor costs.

Moreover, CNC machines can switch between different tools automatically, enabling multiple machining operations to be performed in a single setup. This reduces the need for manual intervention and the time spent on repositioning or re-fixturing parts, streamlining the entire production process.

The result is faster turnaround times for precision engineering projects, allowing companies to meet tight deadlines and respond quickly to changing market demands.

Versatility in Material and Design

CNC machining services provide unmatched versatility in working with diverse materials and producing complex designs. Whether the project requires hard metals like titanium and stainless steel or delicate plastics and composites, CNC machines can handle them all with ease.

Additionally, CNC programming allows for intricate shapes and detailed features that would be challenging or impossible to achieve through manual machining. This capability opens doors for innovation in product design, enabling engineers to create optimized parts that enhance performance, reduce weight, and improve functionality.

Such flexibility is critical in precision engineering, where each component must meet specific functional requirements without compromising on quality.

Consistency and Repeatability

In precision engineering projects, producing a single prototype is often not enough—repeatability is key. CNC machining services guarantee that every part manufactured matches the original design to the highest degree of accuracy. The digital instructions can be saved and reused, ensuring consistent quality across large production runs.

This consistency reduces waste caused by defective parts and minimizes the risk of assembly problems in downstream processes. For industries that require mass production of precision components, CNC machining services provide a reliable pathway to maintain uniform standards and comply with stringent quality controls.

Cost-Effectiveness and Reduced Waste

While CNC machining services involve upfront programming and setup costs, they ultimately reduce overall production expenses. The automation reduces labor costs and improves material utilization by optimizing cutting paths and minimizing scrap.

The precise control over the machining process means fewer mistakes and rework, which saves both time and raw materials. In precision engineering projects, where materials can be costly, this efficient use of resources translates into significant cost savings.

Additionally, CNC machining shortens the product development cycle by allowing rapid prototyping and quick modifications, helping companies avoid expensive delays and accelerate time-to-market.

Enhanced Safety in Manufacturing

CNC machining services also contribute to safer manufacturing environments. By automating complex and potentially hazardous machining tasks, these services reduce direct human interaction with sharp tools and heavy machinery.

This automation minimizes workplace accidents and injuries, ensuring compliance with occupational safety standards. For precision engineering projects involving delicate or dangerous materials, CNC machining provides a controlled and secure production method.

Scalability and Flexibility for Future Needs

As businesses grow and product demands fluctuate, the scalability of CNC machining services becomes a major advantage. The ability to quickly adjust machining programs allows manufacturers to ramp up production or switch to new designs without major downtime.

This flexibility is particularly beneficial for precision engineering projects where design iterations and upgrades are common. CNC machining services enable easy adaptation to evolving specifications and customization requests, supporting innovation and competitive advantage.

Superior Surface Finish and Quality

High-quality surface finish is often a requirement in precision engineering, impacting both aesthetics and functionality. CNC machining services provide superior surface finishes by maintaining precise control over tool movement, cutting speed, and feed rates.

The advanced tooling options available with CNC machines, including specialized cutters and grinding attachments, enhance the quality of the final product. This level of finish reduces or eliminates the need for secondary finishing processes, such as polishing or sanding, which further shortens production time and lowers costs.

Conclusion

CNC machining services have revolutionized the field of precision engineering by offering unmatched accuracy, efficiency, and flexibility. The ability to produce complex, high-quality components with consistent repeatability makes CNC machining an essential tool for industries where precision is non-negotiable.